The Best Guide To Plastic Injection Molding

Wiki Article

Plastic Injection Molding Fundamentals Explained

Table of Contents7 Simple Techniques For Plastic Injection MoldingThe 9-Minute Rule for Plastic Injection MoldingLittle Known Questions About Plastic Injection Molding.Little Known Questions About Plastic Injection Molding.

If you wish to check out better, the guide covers kinds of mould devices, in addition to special ending up processes such as colours & plating. Words that are underscored can be located in the reference in the appendix ... Part I: Moulding: The Fundamentals The Benefits of Injection Moulding Plastic injection moulding is a very exact process that offers a number of advantages over other plastic processing approaches.

Accuracy is best for really elaborate components. Compared to other strategies, moulding allows you to incorporate more attributes at very tiny tolerances. Take a look at the photo to the right. You can hold this moulding in the hand of your hand and it has employers, ribs, metal inserts, side cores as well as openings, made with a moving shut down feature in the mould device.

Using a UK moulder with existing ties to China can remove the threat as well as still result in cost-saving ... Cavity - The component of an injection mould device that offers the plastic product its shape, that does the actual moulding of the plastic. See mould device chapter on web pages 5 and 6 for all terms connected with the mould tool Cycle time - The time it takes for a mould cycle to be finished, i.

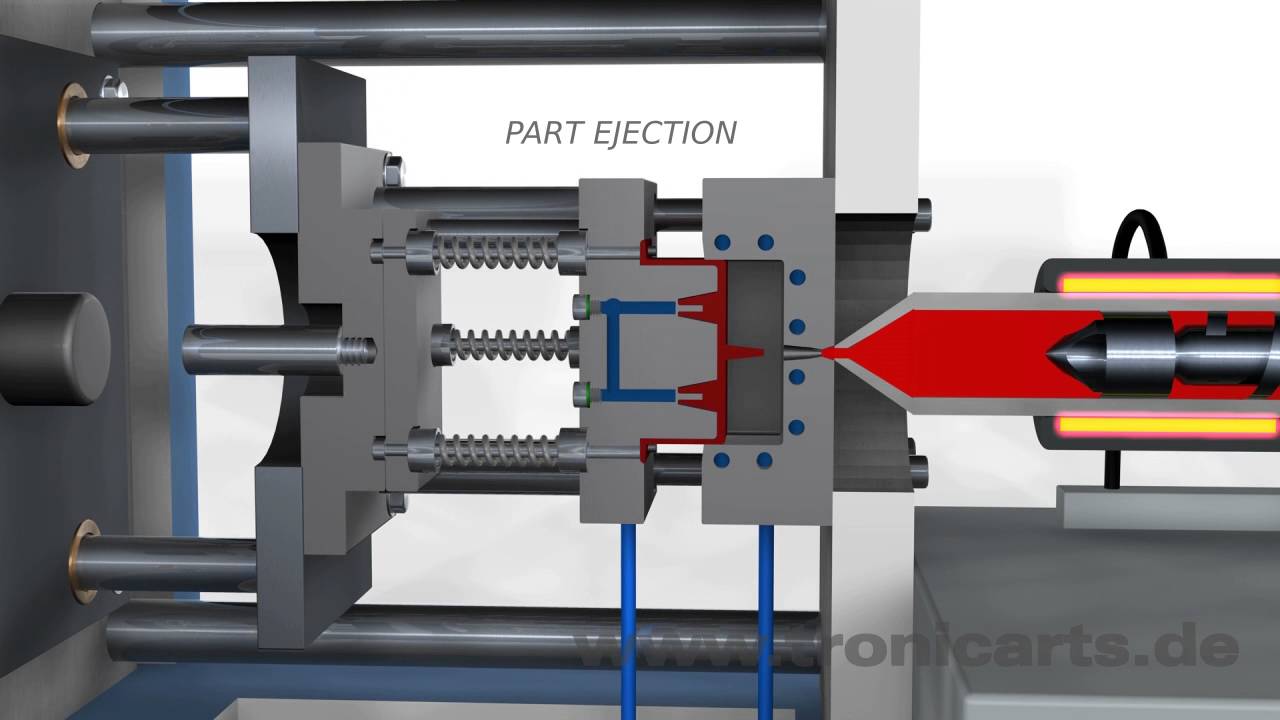

from material feed & melting; material injectionProduct cooling time and ejection to the re-closing of the mould tool ready for prepared next cycleFollowing Draft angles - The wall surfaces of a moulded component should be slightly tapered in the direction in which the part is ejected from the mould device, to permit the part to be expelled quickly (plastic injection molding).

Ejector stroke - The pushing out of ejector pins to expel the moulded component from the mould tool. Ejector stroke rate, size as well as timing requires to be carefully controlled to prevent damages to the ejectors and also mould device, but at the very same time make the moulding cycle as brief as feasible.

Not known Factual Statements About Plastic Injection Molding

Overlocking - When a mould device has actually been established into a moulding maker inaccurately, triggering the device to close as well difficult as well as so harmful the mould tool Part repeatability - The ability to create identical plastic parts time after time Radii - Perfectly straight edges are difficult to expel from the mould device.Ribs - When a plastic component has thin walls, ribs are added to the layout to make the slim wall surfaces stronger Side cores - Side activity which produces an attribute on a moulded part, at an opposing angle to the typical opening instructions of the mould device. The side core needs to be able to pull back as the plastic component can not be ejected or else.

Wall surfaces - The sides of a moulded component The text on this page is a sample from our full White Paper 'Shot Moulding for Buyers'.

Manufacturing procedure for generating parts by infusing molten product right into a mould, or mold Simplified diagram of the procedure Shot moulding (united state spelling: injection molding) is a production procedure for creating parts by infusing liquified product into a mould, or mold. Injection moulding can be performed with a host of products mostly consisting of metals (for which the process you can find out more is called die-casting), glasses, elastomers, confections, as well as most frequently polycarbonate and thermosetting polymers. Shot moulding is commonly used for making a selection of parts, from the tiniest elements to entire body panels of automobiles. Developments in 3D printing modern technology, utilizing photopolymers that do not thaw during the injection moulding of some lower-temperature thermoplastics, can be utilized for some easy injection moulds. Injection moulding utilizes a special-purpose equipment that plastic injection molding has 3 components: the injection unit, the mould and the clamp.

Our Plastic Injection Molding Diaries

In numerous tooth cavity moulds, each tooth cavity can be identical as well as create the very same parts or can be special and also form multiple various geometries throughout a single cycle.

When sufficient product has actually Get the facts collected, the product is compelled at high stress and speed right into the part forming cavity. The specific amount of shrinkage is a feature of the material being utilized, and also can be reasonably predictable. To stop spikes in stress, the procedure normally uses a transfer placement corresponding to a 9598% complete cavity where the screw shifts from a continuous rate to a continuous stress control.

The packing stress is applied up until the gateway (dental caries entry) strengthens. Due to its little dimension, the entrance is usually the initial area to strengthen via its whole thickness.: 16 Once the entrance solidifies, no more material can get in the tooth cavity; as necessary, the screw reciprocates and gets material for the following cycle while the product within the mould cools down so that it can be expelled as well as be dimensionally steady.

Report this wiki page